Stearic Acid Glyceryl Mono Stearate GMS99 & Plastic Additives

Product Details:

| Place of Origin: | MADE IN CHINA |

| Brand Name: | CARDLO |

| Certification: | HACCP, FSSC2200, ISO9001,ISO14001, ISO45001, MUI HALAL, RSPO, REACH, OK KOSHER, FDA certificate etc. |

| Model Number: | GMS40 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1MT |

|---|---|

| Price: | WITH NEGOTIATION |

| Packaging Details: | 25kg/Bag |

| Delivery Time: | within 10-15 days |

|

Detail Information |

|||

| Type: | Lubricants,Dispersant,EPE Foaming Additive, Anti-shrinking Agent | Mf: | C21H42O4 |

|---|---|---|---|

| Other Names: | SE40,distilled Monoglyceride,GMS40,Glyceryl Monostearate,GMS90 | Shelf Life: | 24 Months |

| Color: | Light Yellow | Application: | Antifogging Agents ,PVC, PP Plastic Industry,cosmetic And Medical Industry,plastic,daily Chemical And Food Industry |

| Properties: | White Or Light Yellow Powder | Purity: | 50% Min |

| High Light: | Mono Stearate GMS99,Stearic Acid Glyceryl Mono Stearate |

||

Product Description

Stearic Acid & Glyceryl Mono-Stearate GMS99 & Plastic Additives

Description:

Glyceryl Monostearate & Fatty acid esters GMS 97% powder are non-ionic surfactants with properties (emulsifying, dispersing, foaming, antifoaming, restraining starch retrogradation and controlling fat condensation). With mono-diglyceride concentration of 40-60%

Application:

1. Plastic Additive:

Internal lubricants reduce friction between molecules by weakening the strength between polymer molecules. Thus, they increase production by decreasing viscosity of the polymers. Most of the internal lubricants reduce the glass transition temperature (Tg) and some other properties of PVC. Under normal conditions they do not exudate nor have negative effects on corner weld strength, printability and bonding.

| Application | Feature | Benefit |

| PVC, EPE | Lubricant | With good Lubricating effect, especially between the metal surface of the molding machine and the resin, which can improve the productivity of extrusion molded products and enhance the surface gloss of molded products |

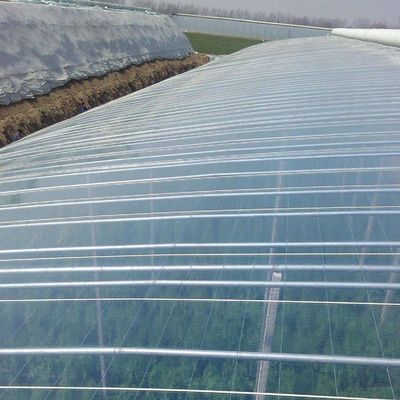

| Agricultural plastic film | Anti-fogging agent | As Anti-fogging agent, it is very safe and efficient. It can be safely used in food packaging materials as Anti-fogging agent. According to different models, it has a long-term dripping effect and can control the dripping speed |

| Wrap | Antistatic | As Antistatic agent, it can make the plastic surface hydrophilic and easily release static electricity. It is suitable for use in electronic equipment packaging, pharmaceutical equipment packaging and other products that require high safety |

2. Cosmetics & Pharmaceutical:

Widely used in ointments, creams and liniments to improve the dispersion and stability of the dispersed phase.

Technical Specifications:

| Inspection items | Standard |

| Appearance | White or light yellow powder solid without impurities, odorless, tasteless |

| Monoglycerides Content | ≥ 95.0 |

| Iodine value | ≤4.0 |

| Free Glycerol | ≤ 2.5 |

| Freezing point | 60.0-70.0 |

| Free acid (stearic acid) | ≤ 2.5 |

| Arsenic (As) | ≤ 0.0001 |

| Heavy metals (plumbum) | ≤ 0.0005 |

Package: 25kg/bag

Shelf life: 24 months

Storage : Keep in a dry, clean and close place, and avoid excessive exposure to light, moisture and air.